REQUEST A QUOTE

Closed Die Forging Design in Salem Ma: A Symphony of Precision

Closed die forging design in Salem, Ma, epitomizes a symphony of precision within the realm of metal shaping. This methodological process involves intricately crafting components by subjecting metal to precise deformation within a set of dies. Precision is paramount in this orchestration, as the closed die technique ensures the creation of high-tolerance and intricate parts that adhere to the exacting standards of Salem's diverse industries. The arrangement and controlled application of force result in a final product that meets stringent specifications. This die-forging process stands as a testament to technical proficiency, showcasing not only metallurgical principles but also an adherence to the intricate details demanded by the industrial landscape. Each operation serves as a note in a calculated symphony, producing components with unparalleled precision, reliability, and adherence to the city's manufacturing excellence.

Upset Forging Die Design in Salem, MA,: Transformative Power in Compression

In the discipline of metalworking, specifically for Upset Forging Die Design in Salem, MA, it emerges as a transformative force in compression-based deformation. This method involves the controlled compression of a metal workpiece, achieved through precisely crafted die design. Precision is paramount as the upset forging process reshapes and densifies the material, altering its form while enhancing its structural integrity. The die design is the linchpin, orchestrating the controlled compression force to ensure optimal material flow and the desired final shape. This method greatly helps by using die design to make strong components with better mechanical properties. Through a calculated fusion of metallurgical principles and engineering expertise, this process exemplifies a technical mastery that aligns seamlessly with the exacting standards of metalworking industries, ultimately delivering components of superior quality and durability.

Cold Forging Die Design in Salem, MA : Redefining Efficiency

Redefining efficiency in the metalworking sector, the innovative cold forging die design in Salem, MA, process stands as a pivotal force. Operating at or near room temperature, this technique not only streamlines production but elevates material properties and surface finishes. Its impact extends beyond the shop floor, contributing to sustainability by reducing energy consumption and minimizing material waste. The industries are experiencing heightened productivity, courtesy of the precision embedded in die design. This method not only meets but surpasses efficiency standards, marking a noteworthy advancement in optimizing performance and resource utilization. It forges ahead in its metalworking endeavors, the transformative influence of cold forging die design showcases a commitment to both innovation and operational excellence.

Drop Forging Die Design in Salem, MA: Precision Through Gravity

The art of drop forging die design in Salem, MA, reaches unprecedented precision, harnessing the formidable force of gravity.This method relies on a heavy hammer's controlled descent onto metal, shaping it with remarkable accuracy. At the core of this process is the drop forging die, accurately crafted tool that guides the force for optimal shaping. Salem's industrial landscape benefits significantly from this gravity-driven precision, producing durable components with reliability and exactness. The controlled impact not only ensures the desired form but also enhances the structural integrity of the final product. It showcases a technical finesse that perfectly aligns with Salem's dedication to precision manufacturing, where the force of gravity becomes a crucial ally in achieving efficiency and excellence in shaping metal components.

Forging Die Design: Where Craftsmanship Meets Ingenuity

The essence of forging die design in Salem, MA lies in the seamless fusion of craftsmanship and ingenuity. This process serves as the bedrock where skilled artisans and technological innovation converge. The thorough planning and execution of die design go beyond mere technicalities; it's an art form. Craftsmanship is evident in the careful shaping of dies, ensuring precision and accuracy in every stroke. Ingenuity comes into play as cutting-edge technology is harnessed to optimize the forging process. It encapsulates the rich industrial heritage, where hands-on expertise meets the advancements of the digital age. This harmonious blend ensures that each forged component is not just a product; it's a testament to the intersection of traditional craftsmanship and modern ingenuity that defines Salem's standing in the world of metalworking.

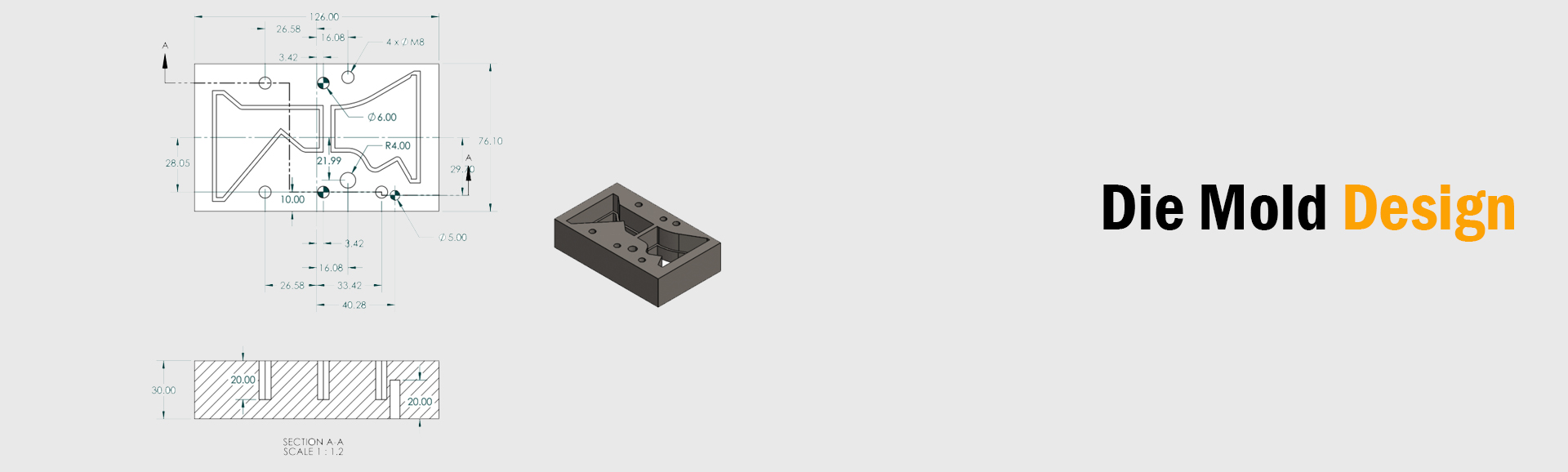

If you seek expert die designing services, 3D CAD Design Service is your definitive solution. We specialise in precision and efficiency, we cater to all your die design needs. Our team of skilled professionals utilizes cutting-edge 3D CAD technology to bring your concepts to life with unparalleled accuracy. Whether you require closed die forging, upset forging, cold forging, or drop forging die designs, our service ensures meticulous planning and execution. We pride ourselves on delivering results that exceed expectations, transforming your ideas into tangible, high-quality components. Trust us for comprehensive and reliable die designing, where precision meets innovation to fulfill your specific requirements with excellence.