REQUEST A QUOTE

Innovative Solutions of Plastic Die Design in Plainfield, NJ

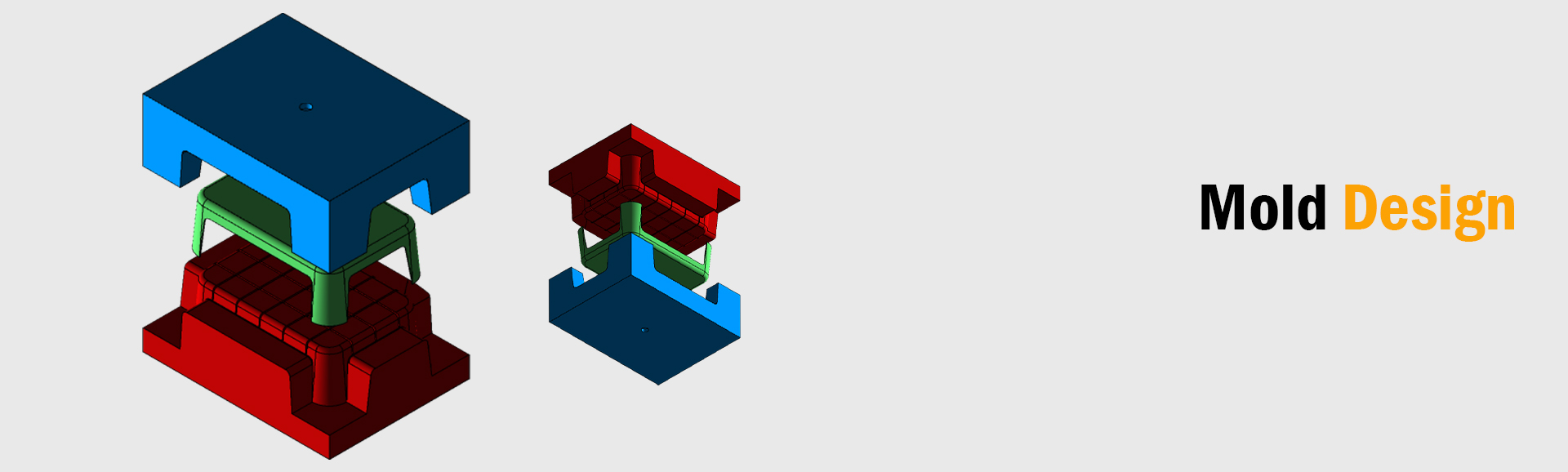

Innovative solutions are revolutionizing plastic die design in Plainfield, NJ, propelling manufacturing into a new era of precision and efficiency. Advanced technologies, such as 3D printing and CAD, are reshaping the landscape, providing manufacturers with unprecedented tools for prototyping and production. The integration of Artificial Intelligence (AI) brings machine learning algorithms to optimize processes, ensuring unparalleled accuracy in die design. Customization and personalization have become paramount, allowing manufacturers to tailor die designs to specific requirements. The emphasis on environmental sustainability is evident, with a shift towards eco-friendly materials and greener manufacturing practices. Design platforms enable real-time interaction among teams, fostering creativity and accelerating the design process. The benefits of these innovations, from economic advantages to industry leadership, underscore the transformative impact on plastic die design in this thriving industrial hub.

Evolution of Injection Molding Die Design in Plainfield, NJ

The evolution of injection molding die design in Plainfield, NJ, has been truly transformative, leaving an indelible mark on the local manufacturing landscape. Moving away from conventional methods fraught with challenges, the industry has embraced advanced designs that harness the power of the latest technologies. This dynamic shift has not only revolutionized the way products are manufactured but has also played a pivotal role in fostering economic growth within the region. The journey from traditional practices to innovative, technology-driven solutions reflects the resilience and adaptability of the manufacturing sector. Today, the impact of advanced injection molding die design extends far beyond the production floor, influencing the city's economic prosperity and positioning it as a hub of progressive and efficient manufacturing processes.

Challenges in plastic moulding die design in Plainfield Nj

- Complex Design Requirements: Designing of Plastic moulding dies faces challenges due to the increasing complexity of design requirements. As industries diversify, the need for intricate and specialized moulds has risen, posing a design complexity challenge for engineers.

- Material Selection Dilemmas: The choice of materials for plastic moulding die design in Plainfield, NJ is critical. Challenges arise in selecting materials that offer the right balance of durability, heat resistance, and cost-effectiveness, considering the diverse range of applications in Plainfield's manufacturing landscape.

- Precision and Tolerance Demands: Meeting tight tolerances and precision requirements is a constant challenge. Achieving uniformity in moulded products demands meticulous attention to detail in die design, particularly as industries in Plainfield strive for higher quality standards.

- Rapid Technological Advancements: The fast-paced evolution of technology poses a challenge for plastic moulding die designers to stay updated with the latest advancements. Adapting to new technologies while maintaining efficiency is crucial for success in Plainfield's competitive market.

- Environmental Sustainability: With a growing emphasis on sustainability, designing plastic moulding dies that align with eco-friendly practices presents a challenge. Balancing environmental considerations with functional requirements adds a layer of complexity to the design process in Plainfield, NJ.

Customization and Personalization mold and die design in Plainfield Nj

Customization and personalization have become pivotal considerations for mold and die design in Plainfield, NJ. Manufacturers are increasingly prioritizing tailored solutions to meet specific requirements, adapting molds to unique geometries and production needs. This trend extends beyond functionality to encompass aesthetic preferences, allowing for personalized designs that resonate with the end user. The flexibility in mold and die customization not only enhances product performance but also addresses the diverse and evolving demands of the market. As Plainfield continues to thrive as an industrial hub, the emphasis on customization in mold and die design reflects a commitment to precision and client satisfaction.

Materials and Methods in Moulding Die Design in Plainfield, NJ

The selection of materials and methods in Moulding Die Design in Plainfield, NJ plays a pivotal role in shaping the efficiency and effectiveness of the manufacturing process. The diverse range of thermoplastics available necessitates a meticulous consideration of material properties, ensuring compatibility with the intended application and production demands. Advanced methods like CAD, contribute to the precision and intricacy of die designs, optimising functionality. Additionally, the integration of innovative materials, like high-performance alloys, enhances the durability and lifespan of moulds, addressing the challenges of high-volume production. In this dynamic industrial landscape, the judicious combination of cutting-edge methods and carefully chosen materials becomes a cornerstone for achieving precision, reliability, and longevity in die design.

If you are in search of unparalleled expertise in injection molding and die design, our 3D CAD Design Service stands as a beacon of innovation and precision in the moulding industry. Leveraging state-of-the-art technologies, we specialize in the seamless integration of CAD and cutting-edge manufacturing methods to deliver superior quality moulds. Our commitment to excellence extends to the careful selection of materials, ensuring optimal performance and durability in every mould. Whether your project demands intricate geometries or high-volume production, our team in Plainfield, NJ, is dedicated to meeting and exceeding your expectations. With a focus on innovation, efficiency, and client satisfaction, we take pride in being at the forefront of moulding solutions, providing customized and reliable services for a diverse range of industries.